Taming the beast! We know the struggle – that feeling when your trusty sewing machine whimpers at the sight of thick, gorgeous leather. Years of stitching delicate silks and breezy cottons haven’t prepared you for this. Fear not, intrepid crafters! We’ve spent countless hours wrestling hides, testing machines, and deciphering specs to bring you the ultimate guide to the best leather-sewing machines of 2024.

Trust our needle-pricked fingers and calloused palms – we’ve found the champions that conquer seams, pierce effortlessly, and leave your leather projects singing (okay, maybe not literally, but they’ll look stunning).

Top 5 Best Sewing Machines For Leather Reviews

- 1. Janome HD3000 – Best Sewing Machine For Leather

- 2. Singer 4411 – Best Sewing Machine For Leather Bags

- 3. JUKI TL-2000Qi – Best Sewing Machine For Leather Upholstery

- 4. Brother ST371HD – Best Sewing Machine For Leather And Canvas

- 5. Janome HD1000

- Do You Need a Special Sewing Machine to Sew Leather?

- Do You Need a Walking Foot to Sew Leather?

- Is it Better to Sew Leather By Hand or Machine?

- What is The Best Thread For Leather?

- What Sewing Needles Go Through Leather?

- What Does 70/10 Mean On A Sewing Machine Needle?

- What Size Needle and Thread Do I Need To Sew Leather?

- What Are Important Factors to Look for in a Leather Sewing Machine?

1. Janome HD3000 – Best Sewing Machine For Leather

Our Pick

- The Janome HD3000 is a fantastic sewing machine that offers exceptional value for its price. It’s easy to use, versatile, and powerful enough to handle even the most challenging projects.

- Whether you’re a beginner looking for your first machine or a seasoned sewist looking for a reliable workhorse, the HD3000 is a great option.

Specs

- 860 stitches per minute speed

- 4mm stitch length

- 7mm stitch width

- 18.7 lbs weight

The Janome HD3000 is a heavy-duty mechanical sewing machine that packs a punch, making it a fantastic choice for both beginners and experienced sewists alike. Whether you’re just starting your sewing journey or you’re a seasoned pro looking for a reliable workhorse, the HD3000 has something to offer everyone.

First Impressions:

Right out of the box, the Janome HD3000 feels sturdy and well-made. The heavy-duty aluminum body exudes a sense of quality, and the sleek black design with red accents is quite eye-catching. The machine isn’t too heavy, making it easy to transport and store, but it feels substantial enough to handle even the thickest fabrics.

Features:

- 18 built-in stitches: The HD3000 offers a versatile range of stitches, including essential utility stitches, decorative stitches, and a one-step buttonhole. This variety allows you to tackle a wide range of sewing projects, from basic repairs and clothing construction to home décor and quilting.

- Easy to use: The HD3000 is incredibly user-friendly, even for beginners. The clearly labeled dials and knobs make it easy to select stitches and adjust settings, and the handy instructional guide located in the top tray door provides helpful tips and tricks.

- Heavy-duty performance: Don’t let the beginner-friendly label fool you. The HD3000 is a true workhorse. The powerful motor can easily handle thick fabrics like denim, canvas, and leather, making it perfect for heavy-duty projects.

- Other notable features: The HD3000 comes packed with additional features that make sewing a breeze, such as an automatic needle threader, a built-in bobbin winder, a free arm for sewing sleeves and cuffs, and a hard carrying case for storage and portability.

Pros and Cons

- Durable and well-made construction

- Easy to use, even for beginners

- Versatile range of stitches

- Powerful motor for handling thick fabrics

- Affordable price

Cons:

- Not computerized, so no fancy features like automatic thread cutting

- Limited stitch selection compared to some high-end models

- Some users report occasional thread jamming issues

Here are some additional things to consider before purchasing the Janome HD3000:

- Your budget: The HD3000 is an affordable machine, but there are even cheaper options on the market if you’re on a tight budget. However, you may sacrifice quality and durability with a cheaper machine.

- Your needs: If you only plan on doing basic sewing projects, you may not need all the features that the HD3000 offers. A simpler and less expensive machine might be a better option.

- Your experience level: If you’re a complete beginner, you might want to consider a machine with even more user-friendly features, such as automatic thread cutting.

2. Singer 4411 – Best Sewing Machine For Leather Bags

Budget Pick

- 69 stitch applications

- 1100 stitches per minute speed

- 4mm stitch length

- 6mm stitch width

If the Janome HD3000 is out of your budget range and you want to sew leather with a slightly cheaper sewing machine, the Singer 4411 heavy-duty sewing machine is a worthy option.

It has a heavy-duty metal frame that gives it stability, and its powerful motor will make sewing a breeze.

It sews at an impressive rate of 1,100 stitches per minute, has a wide range of stitch applications (select them through a stitch selector dial), and comes with an adjustable presser foot pressure to handle a range of fabrics.

To increase your design possibilities, the Singer 4411 comes with four included Presser Feet– General Purpose Foot, Zipper Foot, Buttonhole Foot, and Button Sewing Foot.

This heavy-duty machine machine also features a stainless steel bed plate, allowing you to sew leather with ease – without any resistance.

Additionally, it has adjustable stitch length and width to personalize any project with desired details. You also get a generous “C” space to sew larger projects efficiently.

You get the added bonus of a built-in buttonhole to enhance the sewing results further.

You can adjust the needle to three positions, making it possible to sew zippers or decorative touches with topstitching and cording.

Lastly, you get a top drop-in bobbin with a clear view cover, ensuring your thread supply is always easy to access, wind, and fill.

Pros and Cons

Pros:

- A solid internal frame keeps the machine stable.

- A wide range of stitch applications

- Ideal leather sewing machine for beginners

- Good bang for your buck

Cons:

- It is noisy compared to other sewing machines due to extra speed.

- No automatic needle threader

3. JUKI TL-2000Qi – Best Sewing Machine For Leather Upholstery

Upgrade Pick

- 1500 stitches per minute speed

- 6mm stitch length

- Automatic thread cutter

- 25.4 lbs weight

If budget is not an issue and you want an industrial machine for leather upholstery at a higher price range, JUKI-2000Qi is a reasonable option.

It’s constructed of aluminum die-casting, which makes it perfect for providing industrial-quality sewing.

With a working area of up to 23 inches (with the proper auxiliary table attached), this machine can efficiently work on home decor projects and large quilting projects.

Plus, it offers great convenience with its exclusive foot-controlled trimming system. Have the perfect thread tension and stitch perfections with the speed-control mechanisms every time.

With variable presser foot pressure, you can adjust the settings for thicker fabrics.

The JUKI TL-2000Qi comes with a needle up/down button so that when you stop sewing, the needle position is down, allowing for accurate and free-motion sewing.

And with LED lighting, you’ll have all the visibility you need for even the most intricate projects. And don’t forget the automatic needle threader – no more eye strain and more time for you to start sewing quickly.

It’s also easy to switch out bobbins, thanks to a new bobbin case latch and an enlarged area that makes replacing them a breeze.

For quilters, the JUKI TL-2000Qi also includes a drop feed that allows you to sew curved stitches with ease and accuracy.

Pros and Cons

Pros:

- Metal-based build

- An ample working space makes it suitable for quilting projects

- High stitching speed

- Perfect straight stitches

Cons:

- High Price

- Not portable due to extra weight

- The foot pedal can be too large for some people.

4. Brother ST371HD – Best Sewing Machine For Leather And Canvas

- 37 built-in stitches

- 5mm stitch length

- 800 stitches/minute speed

- 7mm stitch width

With a long-lasting, heavy-duty design, Brother ST371HD can handle any task you throw its way – from thick outdoor fabrics to delicate silks. Enjoy 37 different utility and decorative stitches for blind hems, stretch stitches, and buttonholes.

Plus, 6 additional sewing feet, such as the spring action zigzag, blind stitch, zipper, buttonhole, and button sewing foot, ensure that your sewing projects are always successful.

In addition, the drop feed feature makes free-motion sewing a breeze

It also has an impressive top sewing speed of 800 stitches/minute, so you can complete those sewing projects quickly yet accurately.

Other goodies include:

- A built-in needle threader.

- A drop-in bobbin.

- A free arm.

- An automatic bobbin winding system.

- A Metal needle plate

You’ll also appreciate the mobility of the Brother ST371HD with its built-in handle for easy storage.

The ST371HD has an instructional DVD, so you can learn to use all the features.

It’s equally important to remember that this mechanical sewing machine operates in the U.S. at 120V only.

Pros and Cons

Pros:

- Offers a variety of stitch options

- Affordable price

- Heavy-duty construction

- Simple design

Cons:

- No adjustable presser foot pressure

- It lacks some additional features found in other modern sewing machines, such as a needle up/down button, start/stop button, etc.

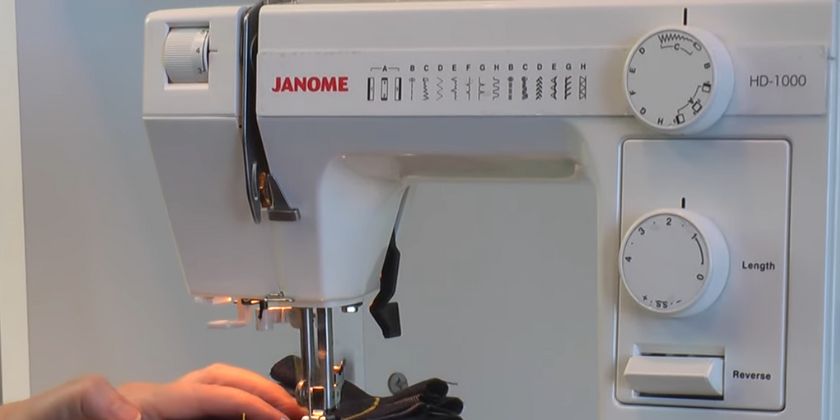

5. Janome HD1000

- 14 built-in stitches

- 4mm stitch length

- 860 stitches/minute speed

- 15 lbs weight

The Janome HD1000 is the heavy-duty machine that we tested in late 2023.

Built with heavy-duty aluminum body construction, the HD1000 ensures you can enjoy a reliable sewing experience. The machine has many features to make your sewing easier, such as front-loading, vertical oscillating hook bobbin, and snap-on presser sewing feet.

With a 5mm max stitch width, the HD1000 can handle various projects, from sweaters to skirts. The removable accessory tray also reveals a handy free arm, so you can easily sew around narrow pieces like sleeves or pant hems.

The Janome HD1000 boasts thoughtful design features, including an intuitive one-hand needle threader to save you from eye strain and markings on the needle plate to provide optimal hem and seam allowance measurements.

With 14 built-in stitches, including utility, stretch, and a 4-step buttonhole function, the Janome HD1000 has all you need to do complex projects. Plus, a handy dust cover is included with the machine.

Plus, the Janome HD1000 comes with several useful accessories, such as extra needles, felt, seam ripper, buttonhole ripper, zipper foot, hemmer foot, and buttonhole foot. And with an automatic needle threader, you can thread the machine without any trouble.

Sewists will love the easy-to-access storage tray on top for tools and accessories, the one-handed needle threader for stress-free threading, and the clear needle plate markings that make measuring hem and seam allowances easier than ever.

Pros and Cons

Pros:

- Simple design

- Extra-high presser foot lift

- Built to handle layers of fabrics, even if it’s leather

- Reasonable price

Cons:

- No speed-control dial

- No start/stop button

Do You Need a Special Sewing Machine to Sew Leather?

Leather requires a different needle, stitch length, and pressure settings than fabric, so working with regular sewing machines can be difficult.

Therefore, your best bet is an industrial leather sewing machine designed specifically for the job. These machines are usually more expensive than a standard sewing machine. But they come with features like automatic thread cutters, adjustable feed dogs, and roller footers – the features you typically don’t get in standard sewing machines.

An industrial machine also has a powerful motor that provides more torque when running through heavy fabric, such as leather, which helps prevent skipped stitches and uneven seams.

Do You Need a Walking Foot to Sew Leather?

In many cases, a standard presser foot won’t be able to penetrate thick layers of leather.

A walking foot provides extra pressure and can handle multiple layers without snagging or puckering the material. The two sets of feed dogs that the walking foot features also ensure even stitching, so you get smoother results than regular sewing feet.

Another benefit of using a walking foot for leather sewing is the reduced risk of damage to your sewing machine from repeatedly sewing a heavy-duty fabric.

Is it Better to Sew Leather By Hand or Machine?

Sewing leather by hand can provide more precise and accurate results in some instances while sewing with a machine can be quicker and result in stronger seams with heavier materials.

Hand-sewing is typically recommended for narrow projects requiring exact stitching or working with thin or delicate leathers like lambskin and suede. It also allows for a greater degree of control over the tension of each stitch, helping to ensure an even seam line that looks clean and professional.

However, it is time-consuming and requires skillful technique. Mistakes made during hand-sewing are more challenging to fix than those made with machines.

Machine-sewn seams are generally considered superior when sewing thicker leathers such as cowhide because they provide extra strength at stress points (pocket corners). Machine stitches won’t pull out from repeated use like hand stitches.

As long as your machine needle is suited to heavyweight fabrics (like size 14/90), sewing pieces together on a machine will produce strong seams that hold up well over time but can also give cleaner results than hand stitching on thinner hides such as lambskin or calfskin.

What is The Best Thread For Leather?

Every type of leather has its own standards and needs regarding sewing threads, making it difficult to pinpoint one single solution that works across all categories.

Here is some general advice to keep in mind:

- Select an appropriate weight according to the thickness and structure of your material. A too-thin thread will not hold well on thick materials and vice versa.

- Choose between polyester or cotton threads, depending on what suits your project better. Synthetics last longer, but cotton has more sheen and softness than synthetic fibers. Also, consider whether you’ll need colorfastness or water resistance (or both).

- Consider waxed/unwaxed thread options – While waxed will be easier for stitching thicker materials like vegetable-tanned leathers due to its higher tolerance for friction, unwaxed is still often preferred due to its smooth feel against the skin when used in garment-making projects such as jackets or footwear items like shoes, boots, etc.,

- Look into specialty threads if needed – Some particular types of leather may require specific kinds of stitching solutions that require higher tensile strength than regular options usually provide.

What Sewing Needles Go Through Leather?

For thin or soft leather pieces, you can use standard lightweight needles with larger eyes for heavier thread finishes (embroidery style). Sharps are also a good choice when sewing through thin layers as they have short, round eyes and sharper points, which will help reduce holes in delicate items like gloves or garments made from lighter-weight skins.

Heavy-duty 90/14 adjustable-size denim needles can be used on light to medium-weight leathers like suede, nubuck, and deerskin. Still, it will likely cause problems if used on thinner skins such as lambskin or vellum unless combined with a suitable presser foot (i.e., ones specifically designed for working with soft materials).

Investing in an attached presser foot is best if you’re using these heavy-duty UD types of needles on multiple projects. Otherwise, you may damage your fabric due to over-punching from the huge eyelet created by this type of needle while stitching.

What Does 70/10 Mean On A Sewing Machine Needle?

70/10 on a sewing machine needle refers to the needle’s size, measured in European and American conventions. For the European sizing, 70 is the size number, and 10 is an associated metric number. This needle would be a 0.9 mm diameter shaft.

In the U.S., this same needle would be called an 11 or 12 (depending on exact size), translating to 1-2 sizes smaller than its European counterpart in diameter measurements of .09mm – .11mm, respectively.

What Size Needle and Thread Do I Need To Sew Leather?

The size of the needle and thread you use will depend on the types of fabrics you’re sewing.

Choosing a medium-weight universal or denim needle in sizes 9/70 – 12/80 is best for lightweight fabrics like lamb skin or soft suede. For thicker materials like cowhide or heavy suede, use 70/10 – 90/14 needles instead.

If the leather is particularly thick (3+ mm), using extra-strong 120/20 leather needles will make it easier to penetrate the tough materials without damaging your sewing machine’s feed dogs and other parts.

Regarding thread sizes for leather projects, heavier threads work best when using heavier-weight needles.

Lighter threads require smaller-sized needles for maximum efficiency and longevity— generally, #46 – #69 for most projects involving lightweight materials such as calfskin or lambskin; 46 – 92 for midweight; 80 – 130 for heavyweight fabrics such as bull hide or thick suede; and 120 – 150 for boot uppers made from heavy hides like pig skin or elk hide.

What Are Important Factors to Look for in a Leather Sewing Machine?

Below are some common factors you need to consider while choosing a sewing machine for leather.

Types of Leather

When selecting a machine for leatherwork, it is crucial to prioritize the type of leather you intend to use. Different machines and techniques are tailored to cater to the specific characteristics of each type of leather.

For instance, lightweight leathers like lambskin or deerskin are more easily sewn by hand than heavier hides such as cowhide or buffalo.

If you’re working with thicker hides, having a machine that can effortlessly guide the leather through the needle and foot plate becomes indispensable.

Additionally, considering factors like stitch length, thread thickness, and tension settings can further enhance your leatherworking experience.

Types of Leather Sewing Machines

Below are the common types of leather sewing machines:

Cylinder arm machines

Cylinder arm machines are ideal for sewing heavy leather. This type of machine has a large cylinder foot that lifts the material and wraps it around the feed dog, allowing you to sew through multiple layers easily.

Flatbed machines

Flatbed machines are great for sewing lighter-weight leathers. They have a flat foot that puts pressure on the material, allowing you to work with thinner leather pieces easily.

Post bed machines

Post-bed machines are great for sewing leather with detailing or intricate patterns. This type of machine has an extended arm that can accommodate larger projects and allow you to sew intricate designs more easily.

Larger Foot Controls

You’ll need a machine with larger foot controls when working with leather. This will help ensure that your hands are in the correct position to guide the fabric and keep it from slipping or bunching up. A larger foot control will also make it easier to adjust the tension settings while sewing.

Presser Foot

The presser foot is a critical component of any machine used for leather sewing. It’s essential to look for a sewing machine with multiple presser feet to choose the right one for your project.

Walking Foot

The walking foot presser is an excellent choice if you’re working with heavier leather. It helps evenly feed the fabric through the machine, preventing it from bunching up or slipping. This type of presser foot is ideal for making even stitches when sewing leather seams.

Teflon Foot

The Teflon foot presser is used when you’re working with lighter leather. It helps reduce friction and prevents the leather from sticking to the footplate, which can cause uneven stitching. The Teflon presser also helps keep the fabric in place while you sew, making it easier to sew straight seams.

Roller Foot

The roller foot presser is ideal for creating a professional finish. Unlike the other presser feet, this one has a roller mechanism that helps pull the fabric through the machine and gives an accurate stitch.